Latest news & events

Our products

Our designers have been working with patient specific implants since 1985, when impressions of the defect used to be the norm, introducing in the late 80s implant design from digital CT data. Integrating technological advancements as they came along, we have now developed an extremely lean design and production system. It allows us to provide our products in a turnaround as quick as 4 days.

Our design experience and many close collaborations with leading surgeons have contributed to the introduction of various features that improve the functionality of the implants. We are also able to cope with out-of-the-ordinary cases.

Key technologies:

- Digital mirror-imaging and warping tools

- RP tooling and 3D printing

- Customised state-of-the-art press

- Pressed and 3D-printed titanium

- Medical PEEK

- Autoclavable nylon

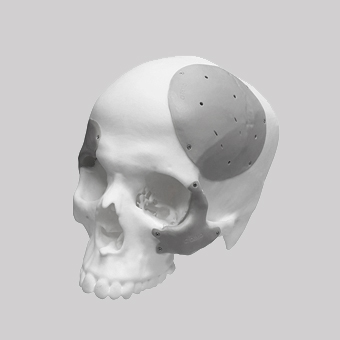

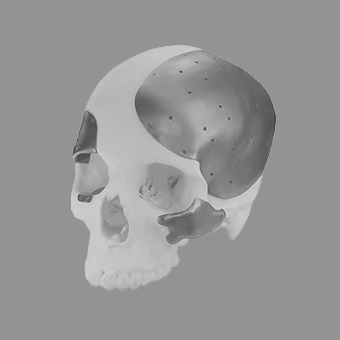

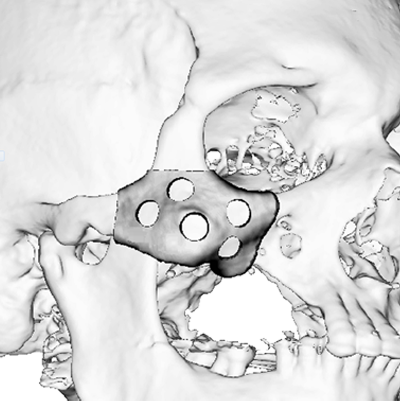

Medical-grade PEEK PSI

Medical-grade PEEK Patient-Specific Cranioplasty and Maxillofacial Implants

find out more

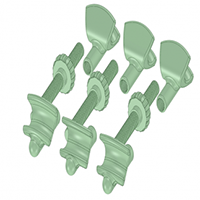

Osteotomy Cutting Guides and Templates

Invaluable Tools to Help You Achieve 2-in-1 Surgeries

find out more